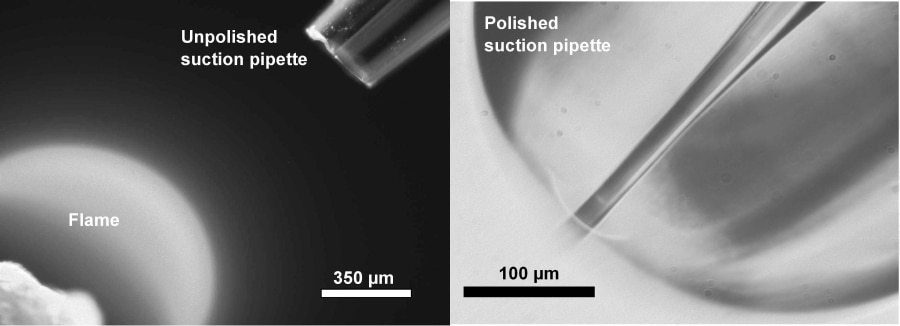

Most microforges suitable for fire-polishing micropipettes are based on resistive electrical heating elements. Such elements, especially those found on homemade microforges, have a number of problems when used for heating large amounts of glass e.g. when polishing suction electrodes (diameter ~15 µm). First, the resistive element is large making the use of high-power objectives difficult. Second, the element moves as it heats up requiring readjustment of its position. Third, large amounts of waste heat (radiant and conductive) are produced; this can damage objectives. Fourth, when run at high outputs they have a limited lifespan. Fifth, elements based on platinum are expensive. Here we demonstrate a very simple and cheap gas-powered microforge with a high (4 W) output of usable heat. It is based upon a disposable cigarette lighter, a length of plastic tubing and a micropipette (GC100T Harvard Apparatus) with a large (~600 µm) tip. To assemble the microforge, the metal cover over the gas nozzle was removed and the lighter gas flow set near to its minimum value (4-10 mg min-1, equivalent to 70-170 µmoles min-1 of butane or ~2 ml min-1). A plastic tube (internal diameter ~0.9 mm) was connected to the gas nozzle and at its other end a 1 mm diameter glass micropipette with a broken tip was inserted. A small wedge can be used to lock the gas flow open. Once the gas is ignited the micropipette tip melts and the gas flow maintains the patent lumen. The gas emitted from the micropipette is easy to light and burns with a clear blue diffusion flame when adjusted to ~2 ml min-1. The flame is reasonably stable (it will withstand air currents of ~0.5 m s-1 Beaufort 0), but some care needs to be taken to shield it from draughts. It can be positioned in any orientation, although we use it mounted horizontally on an inverted microscope allowing the waste heat to escape upwards. A standard disposable cigarette lighter should provide between 3-8 h use. We are using this microforge to fire polish suction pipettes from an internal diameter of ~300 µm down to 15 µm (Figure 1). The main advantage of this gas-powered microforge is that a much larger proportion of the total heat output is available for fire-polishing. Whilst nichrome, Kanthal and platinum melt at ~1400°C, ~1300°C and ~1770°C respectively a butane flame can burn continuously at ~1300°C. The radiant energy from the flame is relatively low compared with a glowing electrical element, allowing it to be positioned directly above the objective and the flame does not move. The majority of the heating occurs as the suction pipette tip approaches within ~10 µm of the flame allowing a reasonably good control of the fire-polishing process without needing to switch off the flame.

University of Cambridge (2008) Proc Physiol Soc 11, DA3

Demonstrations: A simple gas-powered microforge for fire-polishing suction pipettes.

C. J. Schwiening1, L. Caldwell1

1. Department of Physiology, Development and Neuroscience, University of Cambridge, Cambridge, United Kingdom.

View other abstracts by:

Figure 1. Photomicrographs of the gas flame and suction pipette. The left image was taken at low magnification and shows the static gas flame and the cut unpolished pipette. The right image at higher magnification shows the suction pipette polished to an internal diameter of 15 µm.

Where applicable, experiments conform with Society ethical requirements.